The need for surface metrology for the CMP process is evident given that mechanical interaction between the surfaces is a critical variable for all stages of the process. The surfaces that need to be periodically characterized throughout the process include the conditioning disk surface, the wafer surface and the pad surface. In high volume production environments, however, non-destructive in-situ pad characterization at natural pauses in the polishing process (for example, when changing wafers) is desired. This would permit detection of drifts in key pad parameters and assist in validation of process changes. The goal in all cases is to extend the lifetime of consumables and to improve the yield of the whole process.

There are two main factors affecting pad surface degradation and lifecycle – pad groove occlusion and pad glazing.

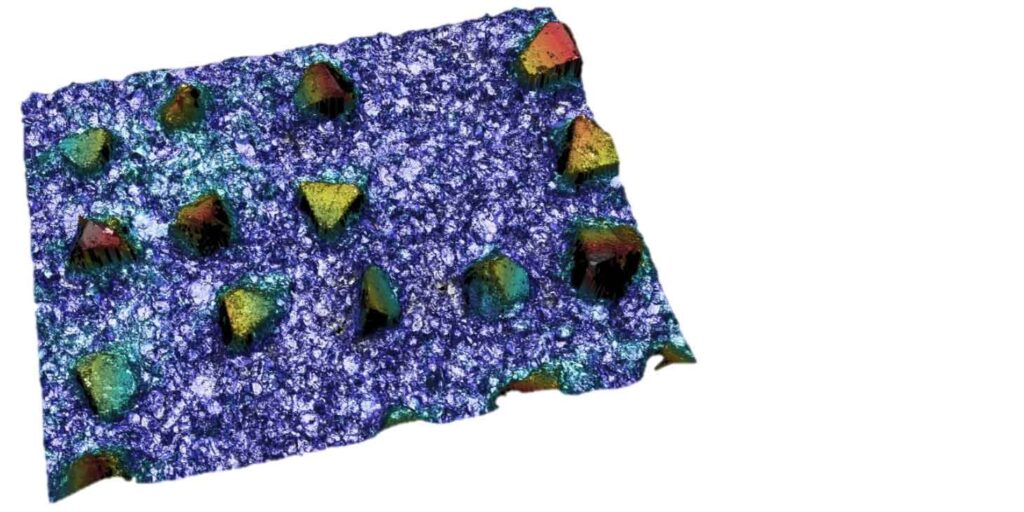

Fig. 1: 3D topography of conditioning disk surface

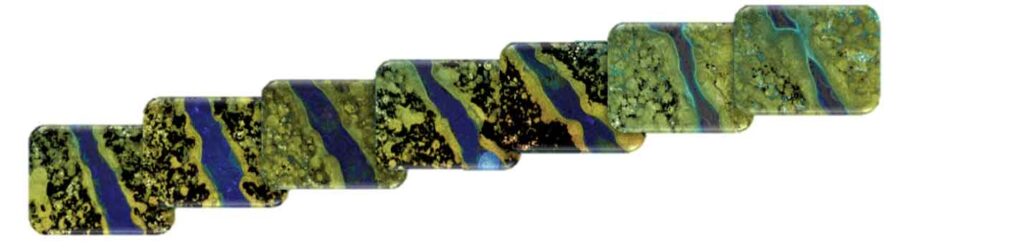

Groove occlusion

During the polishing process the material removed from the wafer deposits in the pad grooves, thus occluding them. This prevents uniform slurry distribution across the water, thus causing non-uniform removal between the center and edge of the wafer. Monitoring of groove occlusion enables prediction of the need to clean the pad grooves and determining the best point in time to do it. This cleaning operation can extend pad lifetime by up to 20%.

Fig. 2: Evolution of pad groove width and depth along 12 hour CMP processing

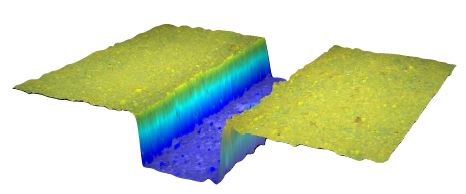

Pad glazing

Glazing is a more complex phenomenon where the polishing ability of the pad is reduced due to surface degradation. This phenomenon enhances wear between wafer and pad, thus increasing process temperature and that may result in material selectivity during polishing. The phenomenon cannot be predicted as easily as groove occlusion and requires constant monitoring in order to guarantee ideal performance of the CMP process. In order to enable in-situ pad surface monitoring, the metrology approach used must be able to work under wet conditions. Only immersion metrology can meet these requirements. The main benefit of this approach is that the pad does not need to be removed from the polisher in order to be characterized. This makes it possible to monitor pad glazing and groove occlusion in-situ at various points in the pad’s life-cycle. In-situ metrology has proven to extend pad lifetime, allowing operators to utilize the pads to the end of their useful life.

Fig. 3: 3D measurement of a new pad groove