Introduction

In tribology terms, sliding wear is defined as the progressive loss of material as a result when two materials are sliding against each other at the contact area under load. Sliding wear occurs inevitably in many different industries where machines and engines are in operation. Typical examples are automotive, machining, aerospace, oil & gas and many more. Sliding motion causes serious mechanical wear and material transfer at the surface, which may lead to reduced production efficiency, machine performance or even failure.

The MFT5000 is a versatile system to characterize mechanical properties and capable of simulating a vast number of tribology and wear tests on the same platform. This application note shows how the MFT5000 can be used to study grease/oil for Extreme Pressure (EP) and wear tests using its Block-on-Ring (BOR) module. Using this module, the MFT platform can perform several standardized tests such as ASTM D2981, D3704, G77, G176, D2509, D2714, D2782, Timken OK Load test, but also customized tests.

Experimental Setup

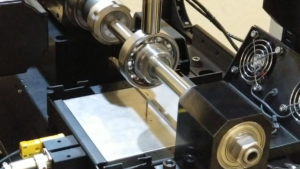

The Block-on-Ring module on the Rtec Instruments Tribometer is capable of simulating a variety of harsh field conditions. Reliable and repeatable measurements can be performed under elevated temperatures, high sliding speed and high contact pressure. The friction coefficient is dynamically calculated by the acquisition of both down force and torque on the rotational shaft. It helps to determine coefficient of friction, wear rate, volume of wear and Extreme Pressure (EP) but also wear resistance of lubricants, greases, bearings and shafts. The test can run under a wide range of load, sliding speed, rotational speed and temperature.

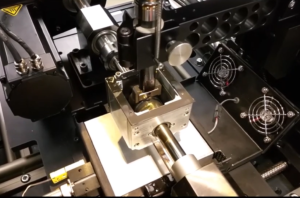

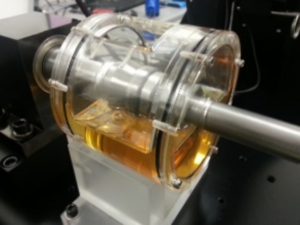

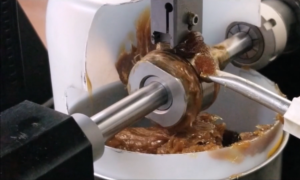

Oil or grease is placed inside the liquid container with an attached heating chamber. A typical test is set up for up to 50 ml lubricant (see figure 1) with available options to test up to 3500 ml of lubricant (see figure 2). There are provisions available to recirculate lubricant (oil or grease) to a predetermined flow rate. The block corresponding to the referred standard is mounted on the self-levelling upper holder to create a conformal contact between the upper and lower sample.

Fig. 1: Test setup for typical test on Block-on-Ring module

Fig. 2: Test setup for large volume liquid container

Method

- Extreme Pressure – This method covers the determination of the extreme pressure (EP) characteristics of oil or greases in sliding applications. Load is increased in stepwise mode or linear mode until there is seizure or sudden increase of coefficient of friction during the test. This method is commonly used in Timken OK test for grease and lubricants (ASTM D2509 and D2782). The wear on the sample is evaluated to determine pass/fail criteria for the lubricant at the load being tested.

- Wear Test – This method covers the determination of the friction and wear characteristics of greases or oil in sliding applications. Depending on the application and test requirements, the samples can be submerged, or the lubricant can be circulated using pumps or grease dispensers at pre-defined flow rates. The test can also be used to evaluate tribological and wear properties for solid lubricants and coatings. The test can be easily configured by defining the temperature, loading rate, test load and rotational speed. The rotating shaft is supported from both ends to prevent bending under high loads.

- Customized Test – Block-on-Ring module is a highly versatile module and can be used to perform many customized tests such as oscillating tests, where the rings are oscillated clockwise and counter-clockwise to a pre-determined angle or numbers of rotations. These tests are frequently performed to evaluate the performance of solid lubricants, coatings or surface texture on bearings and in applications where there is frequent change in direction or limited motion between the two counterparts. Customizable nature of Block-on-Ring modules allows real components including shafts, bearings and their counterparts to be mounted without specific modification.

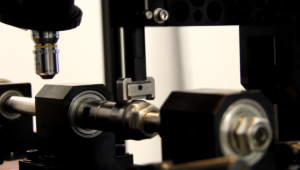

Fig. 3: Ring Test with inline 3D profiling

Fig. 4: Test setup for bearings

Fig. 5: Block-on-Ring for custom bearings

Fig. 6: Test setup for Grease OK Load test

Analysis

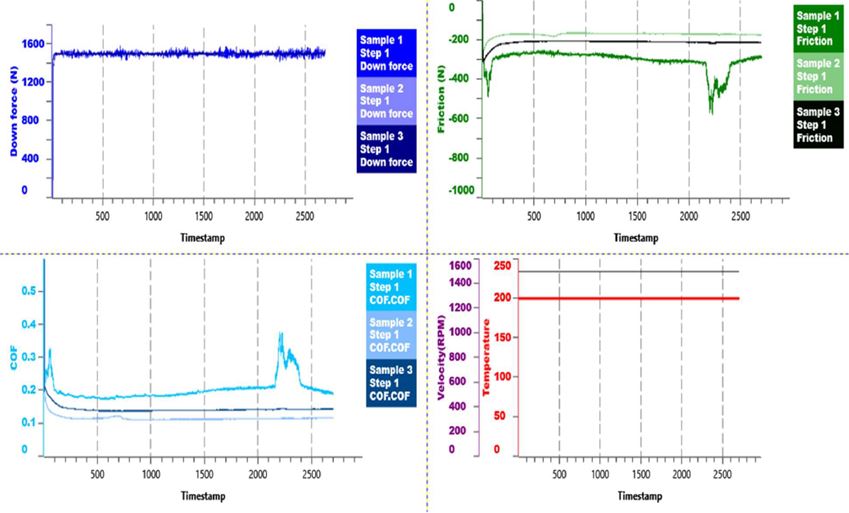

Figure 7 below shows the comparison of different lubricants as tested using the Block-on-Ring module on a HRC30 block against a Timken rig, under constant load (1500N) and velocity (1500 rpm) at 200°C.

Fig. 7: Comparison of three lubricants using the Block-on-Ring module at 200°C, 1500N, 1500 rpm rotational speed.

The normal load (Down Force) is controlled by force feedback. Sample 1 shows a sudden increase of friction coefficient, caused by seizure.

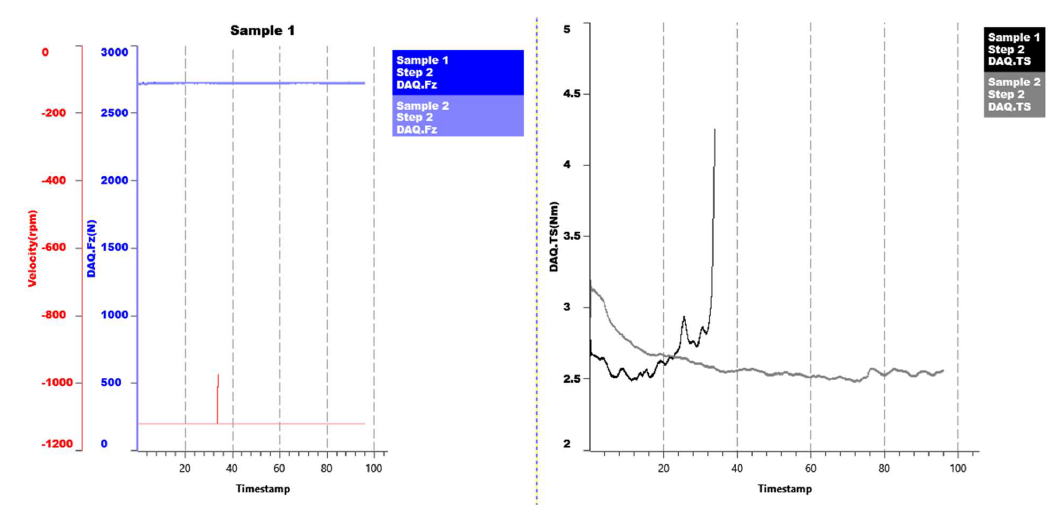

Figure 8 shows the EP wear test (modified Timken OK test conditions) for two different lubricants on the Block-on-Ring module. The test is stopped automatically when the friction force, inline torque or coefficient of friction increases drastically showing onset of failure. The test was set up to run for 90s, at 2700N, 1150 rpm at room temperature. Sample 1 failed with in 30s, while sample 2 could run for the full duration of the test. The test for sample 1 was stopped automatically when the torque increased drastically.

Fig. 8: Comparison of 2 products for EP wear properties of lubricants using Block-on-Ring module. Test conditions are at 2700N normal load, 1150 rpm rotation speed and test duration of 90 seconds.

Conclusion

The Block-on-Ring module on the MFT5000 platform is an excellent option to run tests in Block-on-Ring mode. The load can be applied up to 10.000N with a precise temperature control (up to 500°C) and monitoring with high data acquisition (up to 200 kHz). Several ASTM and customized tests can be carried out on the MFT5000 by adjusting the volume and flow rate of lubricant, loading rate, applied load, speed of rotation and temperature. Several customized tests can also be performed on this module including testing real components. This module is useful to characterize tribological properties of additives, grease, oils, coatings, solid lubricants, bearings, shafts etc. Moreover, the equipment can be upgraded with additional interchangeable modules to perform other types of tribological tests.

Keywords

ASTM D2981, D3704, G77, G176, D2509, D2714, D2782, Timken OK Load, Block-on-Ring.