Whirling inserts are used to produce threads. The whirling process is complex, that’s why there are many different angles (lead angle, angle of rake, clearance angle) on an insert (Figure 1a). In addition, there are inserts with up to 3 teeth on it. This makes it very difficult to measure an insert.

For previous quality assessments, one had to rely on simple optical devices for assessing the dimensional accuracy and on stylus devices for measuring roughness. The informative value of these measurements, however, is very limited. In addition, the parts often had to be destroyed so that the desired size could be measured. In order to constantly improve the quality of our tools, there is a need for a flexible device to measure and assess both critical dimensions and surface roughness of cutting tools.

The purpose of this case study is to measure the cutting-edge radius of an insert with a 3D optical profiler and also extract the roughness parameters along the edge of the cutting tool. A schematic drawing of the insert to be measured is shown in Figure 1b.

Figure 1a). Some of the parameters of interest in a cutting tool. b) Drawing of the measured insert. The red line shows cutting edge profile that is under evaluation in this case study

Measurements

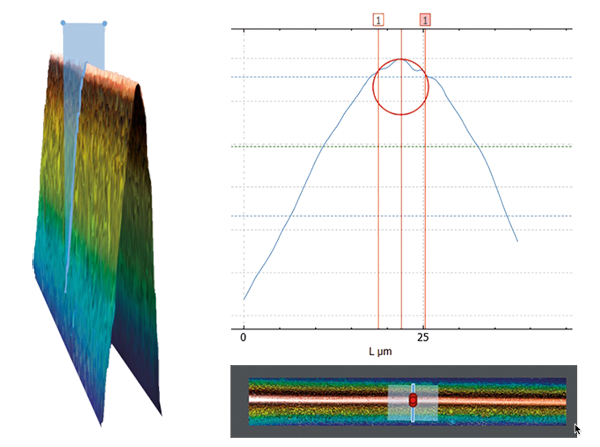

The cutting-edge radius is very important for a good tool life expectancy. For this particular application note, we used the Fixe Axis 3D Optical Profilometer in Focus Variation HDR mode (Sensofar), in conjunction with a 100X Objective magnification, to acquire the cutting edge 3D topography of an insert (Figure 2). It is worth noting that for this particular sample, a Confocal technique would have provided accurate and robust results as well. The insert was held as shown in Figure 3 with an elevation angle of 63.5°.

Figure 2. On top we see the 3D topography of a rounded cutting edge measured with 100X Ai Focus Variation HDR. The transversal profile is shown at het bottom and the top-view on the right hand side

Learn More?

Please click on ‘Request Application Note’ and download the full application note ‘Cutting edge measurement of an insert’.