Foundry components require many controls and inspections during the overall production process. X-ray Computed Tomography (also known as CT) is a powerful non-destructive technology to easily inspect every sample and the only one giving the ability to see inside the matter.

Computed Tomography: exploring foundry components and optimizing production process

Foundry components are diverse and widely used in many industrial fields such as the automotive and naval industries. These components have materials behavior displaying a range of failure modes.

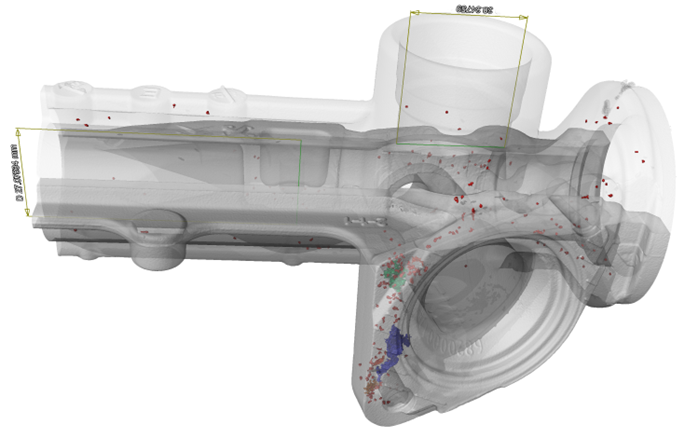

Industrial CT scanning technology is the only inspection technique able to characterize in an easy way the overall material structure of a foundry component. CT scan provide precise measurements of the overall sample, from the whole structure down to individual porosity level. Every structural and dimensional aspect of casting parts can be assessed through one CT dataset.

Structural analyses: casting products validation

Industrial CT scanning offers quick and accurate inspection of parts’ internal and external structures. With a resolution up to 5μm, RX Solutions CT systems and software enable the validation of tiny details on casting components. It is possible to define and export an accurate 3D model of the sample to make measurements of the inner and outer geometries, on simple or multi-material parts.

In the field of industrial research, nano inspection is widely used, to observe and characterize foundry components. Understanding the microstructure role helps to prevent cracks that can propagate through the intermetallic phases.

Learn More?

Please click on ‘Request Application Note’ and download the full application note ‘Foundry & Weldings – Material inspection of foundry components’.