In-situ tensile SEM experiments enable real time observations of material behavior after a predefined stimulus to examine crystal deformation and crack growth until material failure occurs. Versatile systems, like the ultra-high resolution SU7000 field emission SEM, are designed for such applications. The SU7000 is manufactured by Hitachi High-Tech and has many functionalities such as wide-area observation, variable pressure and a large specimen chamber to accommodate sub-stages.

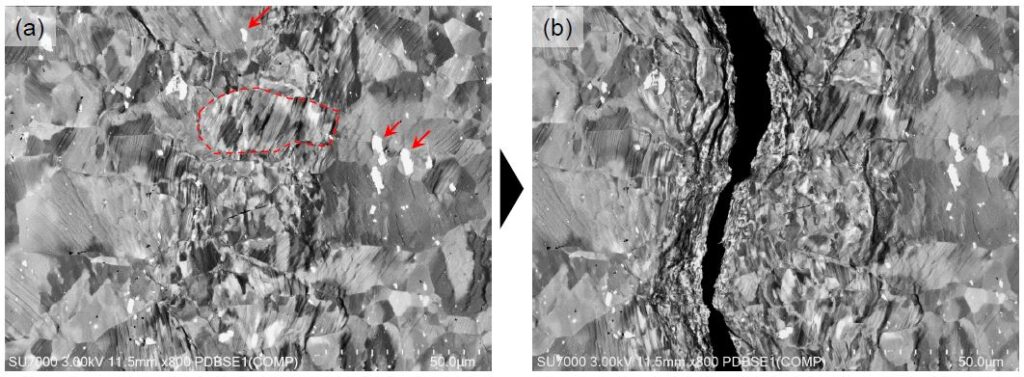

This application note describes an in-situ SEM observation of a fracture process of an aluminum plate and was performed using a tensile sub-stage. Figure 1(a) shows a BSE image of a polished aluminum plate under tensile stress before the fracture. The red arrows indicate material contrast of precipitates and channeling contrast is clearly visible too. This effect is especially observed in the middle of the field of view (red broken line): channeling contrast changes drastically in each crystal grain.

Figure 1. In-situ tensile experiment conducted in a SEM on an aluminum plate. Images show material behavior during applied tensile stress (a) and after material failure (b).

Figure 1(b) shows a BSE image of the same field of view as Figure 1 (a), and was taken after the fracture due to additional accumulation of stress. These in-situ SEM images also reveal elongated crystal deformation and structural refinement of the crystal grains near the fracture edges.

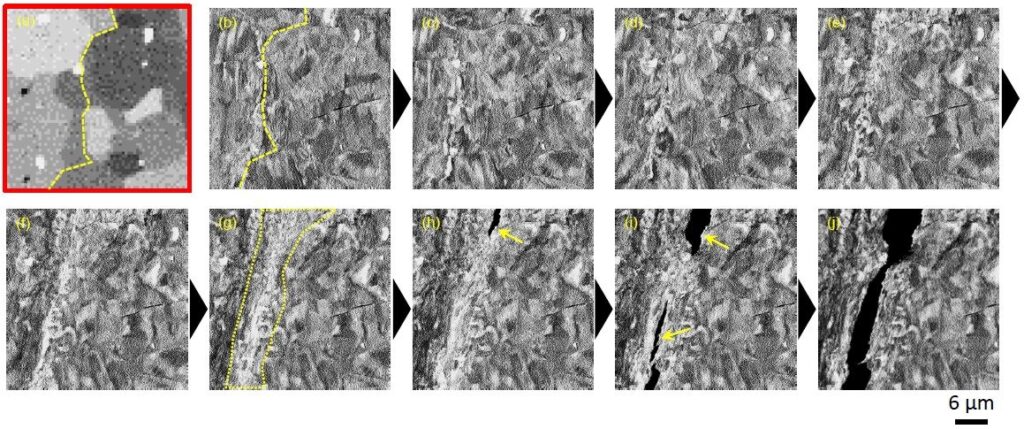

Figure 2 (a-j). Snapshots from the in-situ tensile testing process of an aluminum plate in a SEM

The in-situ tensile SEM fracture process was recorded as a movie and individual snapshots are depicted in Figure 2. Figure 2 (a) is a digitally zoomed image of a wide area image taken before the tensile experiment. The broken yellow line shows the grain boundary where fracture will occur. Figures 2 (b) – (j) are snapshots from the in-situ SEM footage. As the tensile stress increases, grain fragmentation gradually occurs around the original grain boundary. Cracks were generated and the specimen was finally torn along the grain-refined area as shown by dotted line in Figure 2 (g). This application note demonstrates how the dynamic behavior of crystal structures can be visualized in real time by in-situ tensile SEM experiments.