In this Application Note, we will focus on the analysis of those fibers ranging from 800 nm to 22 microns as well as fibers with surface treatments, using the mIRage+R, IR+Raman microscope, based on the newly pioneered Optical Photothermal Infrared (O-PTIR) spectroscopy. All fibers have been analyzed directly without applying additional modification or sampling accessories. The resulting O-PTIR spectra resembles the transmission-like IR spectra in non-contact (far-field) mode. Spatially resolved (micron) spectra reveal the distribution of the surface treatment on the micron-sized fibers without dispersive/scattering artifacts.

Finally, we further extend the application of mIRage into the analysis of a single nanofiber of 800 nm to complete the possibility of analyzing the full-sized range of fibers for forensics, textiles, filtration, medical scaffolds, art conservation, microplastics, and intellectual property protection.

Introduction

Fiber identification and characterization often relies on collecting infrared spectra using an FTIR microscope and then comparing the spectra with commercial or custom IR databases. The dimension of a fibrous filament can be greatly varied, from sub-micron to many tens of microns diameter, which covers approximately the wavelength of the infrared light used to measure the fibers. At this regime, infrared light could be scattered and dispersed leading to baseline offsets and tilts, rendering the use of reflection mode FTIR on fibers impossible.1, 2 Potential solutions may include flattening of the fiber with roller knives3 or by a diamond compression cell or by using a micro ATR accessory. In doing so, the fibers can be damaged and/or the molecular orientation modified, which if these are trace samples, could compromise its accurate characterization. Forensic applications are particularly vulnerable due to limited availability of the evidence. These limitations are equally applicable to newly emerging QCL IR microscopic technologies as well. To date, these issues have placed restrictions on how effectively IR microscopy has been used for fiber analysis.

The aforementioned issues are essentially eliminated with the advent of Optical Photothermal Infrared (O-PTIR), which operates by exciting the sample with IR light from a widely tunable and pulsed QCL to induce a localized modulated photothermal effect. A 532 nm probe laser is co-localized with the IR light for detecting the effect and defines the spatial resolution rather than the long IR wavelengths. This effectively breaks the diffraction limit suffered by traditional FTIR/QCL microscopy.

Experimental

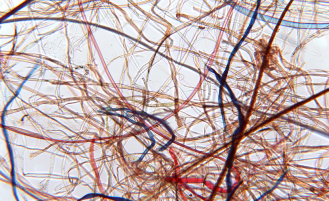

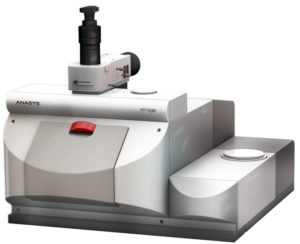

An eight factor multi-fabric test sample was obtained from Kimble. A short strip of the fabric was cut from the bundle and placed directly into the sample chamber of mIRage+R Infrared and Raman Microscope, pictured in Figure 1, with a piece of adhesive tape without additional sample preparation.

Figure 1: The mIRage O-PTIR instrument, Photothermal Spectroscopy Corp., Santa Barbara, CA

Learn More?

Please click on ‘Request Application Note’ and download the full application note ‘Submicron, simultaneous and non-contact IR+Raman spectroscopy for direct fiber characterization’.