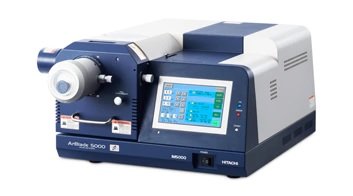

Sample preparation is often required before scanning electron microscope measurements can be performed. Cutting and polishing are common preparation techniques to remove surface roughness and to obtain a flat surface. Such traditional mechanical techniques apply shear forces to the sample, which result in surface artifacts like scratches, smearing, delamination and other damages at soft materials. All these issues are circumvented with the latest ion milling techniques developed by Hitachi High-Tech. These systems apply a broad low-energy Ar+ ion beam to sputter sample material from the sample and can be used both as cross section polisher and surface polisher. No mechanical stress is applied, which leaves extremely flat surfaces and cross sections without any artifacts.

Key Features and Benefits

Key Features and Benefits

♦ Dual milling configuration in a single instrument

♦ Cross-section milling rate of 1 mm/hour

♦ Cross-section widths up to 8 mm

Applications

Applications

♦ Polymers

♦ Metallurgy

♦ Microelectronics

About Hitachi

Hitachi High-Tech Corporation, provides a wide variety of scientific instruments. Their innovative R&D approach enables them to provide world-class solutions in the fields of materials sciences, life sciences, energy storage and semiconductor.

Why Hitachi?

♦ Key player in the market of Electron Microscopes

♦ Creative, leading-edge technology

♦ Complementary product range

Related products

Related products

Scanning Electron Microscope deliver both operability and expandability

With revolutionary computer-assisted EM Wizard technology

Compact variable-pressure SEM with unparalleled image resolution