Optical Profiling

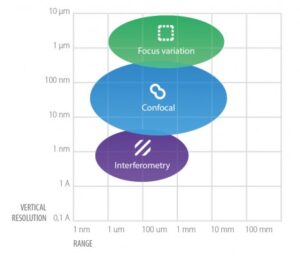

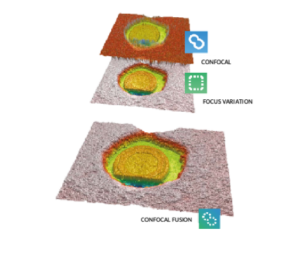

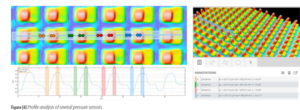

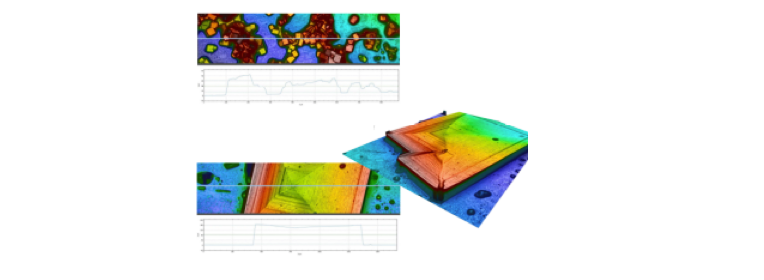

If you need to characterize features at micrometre to sub micrometre on natural or manufactured surfaces, an optical profilometer will provide 3D surface metrology without any – potentially destructive – surface contact. This is a crucial advantage of optical profilometry over tactile (stylus-based) techniques.Other advantages of optical profilometers are speed, reliability and large field of view. Depending on the required resolution and the properties of the material, different optical techniques are available. ST Instruments’ portfolio includes a range of optical surface profilers using one or multiple technologies such as confocal microscopy, interferometry and/or focus variation. These instruments are produced by Sensofar.