Smooth surfaces hold pivotal roles in various industries, ranging from optical devices to semiconductor manufacturing. The quality andprecision of these surfaces directly influence the performance of end products or components, making accurate surface characterizationa mandatory step on their manufacturing process.

What is a super smooth surface?

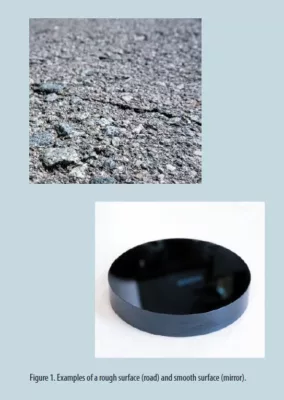

The definition of smoothness can vary depending on the application or industry. For instance, what may be considered smooth in engineering may not meet the criteria for smoothness in optics. Besides, non-technical definitions of smooth surfaces can be subjective, encompassing visual perception and tactile feel. While these subjective definitions may be intuitive for everyday use, we need more precision and reproducibility for rigorous measurement and analysis. One approach to address the challenge of generally defining smooth surfaces is to consider them as such when their roughness is significantly smaller than the observation scale. In other words, a surface can be deemed smooth if its irregularities are negligible compared to the observation or measurement scale analysis.

This perspective acknowledges that the perception of smoothness is relative, and what may be considered smooth at one scale of observation might exhibit imperfections when examined at a finer resolution. For example, a surface with a roughness of a few micrometers may be regarded as smooth when analyzed visually but may appear comparatively rough when observed using a microscope.

Learn More?

Please click on ‘Request Application Note’ and download the application note ‘Measuring Super Smooth Surfaces’.