PiQ Nanoindentation Tester

♦ SMT-2000 | Measures surface properties such as hardness and elastic modulus at the nanoscale

Surface Materials Tester

♦ SMT-5000 | Benchtop platform to characterize mechanical properties with in-line 3D profiling

High Temperature Hardness Tester

♦ High Temperature Hardness Tester | Conventional Hardness testing up to 1200°C in oxygen reduced atmospheres

What is the operating principle of Instrumented Indentation Testing?

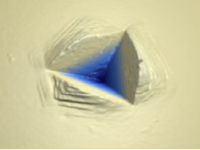

Micro Indentation and Nano Indentation testing are based on the same operating principles: a well-defined indenter/tip (often diamond or tungsten carbide) is driven into the material using a pre-defined load, while the system is measuring the vertical displacement (indentation depth). Nano indentation is typically performed by using a 3-sided geometry tip (e.g. Berkovich or Cube corner), where Micro Indentation can also be done by using a 4-sided indenter (Vickers, Knoop).

The Rtec Indentation Testers are using piezo actuators for precise motion control, while capacitive sensors measure the vertical displacement (depth) with high accuracy. Before running a series of multiple measurements, the operator sets the parameters in the software and saves them as a ‘recipe’. Important parameters are the maximum normal load, loading rate, type of loading, approach speed, pause time at maximum load and the unloading rate. Single or multiple measurements can be programmed in an array or at randomly chosen positions.

When the measurements are finished, material parameters are displayed including the statistics such as the average, median and standard deviation of hardness, Young’s modulus, stiffness and creep.

Why use Instrumented Indentation Testing?

The SMT-5000 platform offers the possibility for running micro indentation and nano indentation experiments by the modular interchangeable design. The traditional hardness tests (Vickers, Knoop, Rockwell, Brinell) are commonly used for bulk-materials, and require the accurate measurement of the resulting imprint. This could be very challenging and inaccurate, especially when a minor load is applied, which results in a small imprint. Also, it only provides information about the hardness of the material and does not give any other material properties (such as elastic modulus, storage/loss, creep or stiffness).

By contrast, the depth-sensing Micro- and Nano Indentation Testers can also be used for thin films, coatings and to determine material properties at local sample positions. Nano- and Micro Indentation measure the penetration depth as a function of the applied load. This provides the operator valuable information about the film/coating material properties at the top surface and, when increasing the load, also at the substrate interface.

For accurate measurement of coating and thin film properties, it is essential to apply the 10% rule; the maximum indentation depth should not exceed 10% of the coating/film thickness, as the applied load creates a stress in the material, which could affect the indentation depth.

Applications for the indentation tester:

Instrumented Indentation Testing is widely used for all types of materials and products. Where the traditional Vickers, Brinell and Rockwell hardness testers are mostly used for hard coatings and bulk materials, the Nano- and Micro indentation testers are used in an extensive range of materials in both R&D and quality control laboratories to characterize thin films, polymers, metals, alloys, glass, composites etc.

The Rtec Instruments Indentation testers are compliant to several different international standards:

ASTM E2546, ASTM B933, ASTM D785, ASTM E140

ISO 14577, ISO 6508, ISO 6507, ISO 4516

DIN 50359, DIN 55676, JIS B7734

Automotive:

Paint, Varnish

Polymer

Engine, piston

Thermal spray

Window and glasses

Hard coating:

TiN, WC, DLC, TiAlN

Cutting tools, drills, inserts

PVD, CVD coatings

Forming tools

The4rmal and plasma spray coatings

Bio-materials:

Implants, stents

Bone tissue

Tablets, pills

Drug delivery

Artificial joints

Materials:

Ceramics

Polymers

Metals

Rubber

Composites

Semiconductor:

Thin films

Low-K films

Passivation layers

MEMS, NEMS

Hard disks

Optics:

Eye glass, lenses

AR coatings

Mirrors

Touch screen

Display panels

Decorative coatings:

Jewellery

Watches

Evaporated metals

Cases

Anti-corrosion coatings