How does a Tribometer work?

In essence, a tribometer allows you to bring two surfaces into contact under highly controlled conditions. Typical setups of the system are Pin/Ball-on-Disk (rotational wear), Linear reciprocating (e.g. piston movement), Block-on-Ring (lubrication, wear), Twist Compression Tester (evaluating lubricants, materials and coatings), Fretting Tester (high frequency, small amplitudes oscillations), 4-Ball tester (lubricants), Tribo-corrosion (the combined effects of mechanical and chemical interaction between materials).

The interaction between surfaces can be modified by adding liquids, lubricants or abrasive particles. The tests can be performed under a wide set of controlled conditions. Variables are, among others, temperature, contact pressure, humidity, or type of gas. Interchangeable modules will help you to adjust the tribotester according to your needs.

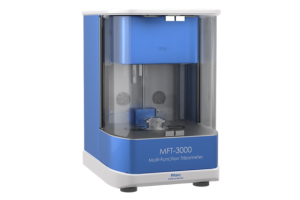

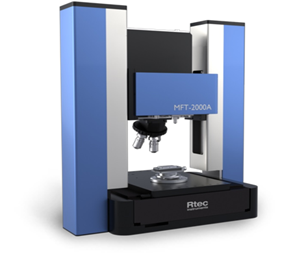

Interchangeable modules on the Tribometer systems provides optimum flexibility in testing your applications. This system covers a wide range of forces, from nano tribology to heavy load measurements.