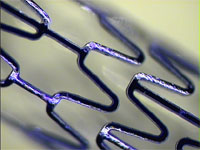

The use of biomedical implants, like artificial joints, screws or stents is ever increasing. These products are coated, for example to protect them from infections, reduce wear or regulate friction. To guarantee a long life for these implants and to minimise any inconveniences for the patient, the coatings must be tested for characteristics like adhesion, friction and wear.

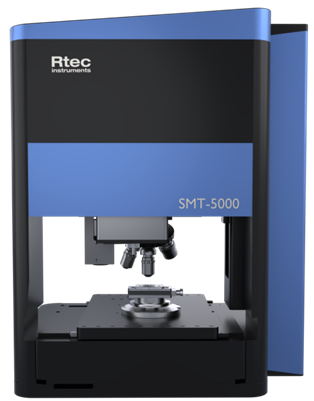

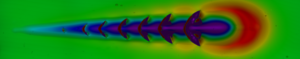

The Rtec Instruments 3D scratch testers can be used to investigate the properties of thin organic coatings or hard metal-based PVD (physical vapour deposition) coatings, as well as polymer coatings. For example, by making a well-controlled scratch on the surface of an implant and measuring the characteristics of this scratch using the in-line 3D Profiler, it is possible to measure adhesion and wear of their coating.