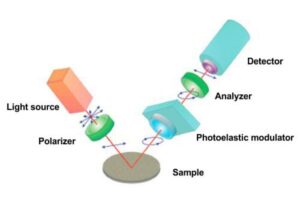

Spectroscopic Ellipsometry

Spectroscopic ellipsometry is an excellent choice if you are looking for a non-contact, non-destructive technique to characterize thin films or surfaces. This is an optical technique using linearly polarized light which is reflected from the surface. The interaction with the surface alters the polarization, which results in an elliptical signal. This signal carries information on the sample’s composition. Spectroscopic ellipsometry can characterize a wide number of surface properties in a wide range of materials.