“In the tooling industry, optical metrology is crucial in achieving success from both design and tool use perspectives. Optical profilometers provide valuable information to help manufacturers optimize their tools and processes”

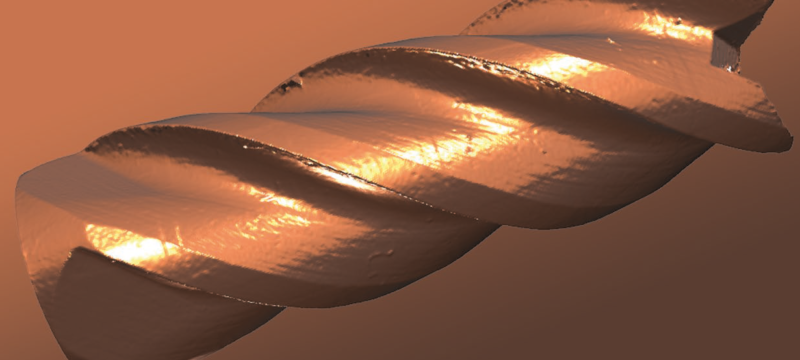

One of the critical applications of optical metrology in tooling is the dimensional characterization of cutting tools to ensure that tools perform optimally and have a long service life. In addition to dimensional characterization, roughness measurements can be interesting for predicting how well the removed material will exit the tool. This information is critical in preventing clot formation or overheating of the tool during use.

Optical metrology systems can also provide local measurements to help identify potential cutting tool issues. For example, these systems can detect chipping or coating peeling, indicating that a tool needs to be replaced or repaired.

Learn More?

Please click on ‘Request Application Note’ and download the full application note ‘Multi-perspective characterization of an end mill’.