♦ Auger | High spatial resolution Auger imaging performance for the most demanding AES applications

Table Of Contents

How does Auger Electron Spectroscopy work?

Auger Electron Spectroscopy (AES) is a surface analysis technique used to investigate the composition and chemical states of materials. It relies on the detection of Auger electrons, which are emitted when atoms in a sample undergo transitions to lower energy states. AES provides valuable information about the elemental composition and chemical bonding of the top few atomic layers of a material’s surface.

Here’s a summary of how Auger Electron Spectroscopy works:

- Principle of Auger Emission:

Auger emission is a process that occurs when an electron transitions to a lower-energy state within an atom, molecule, or solid. This transition leaves a vacancy in an inner electron shell. To fill this vacancy, an electron from a higher energy level drops down, releasing energy in the form of an Auger electron.

- Excitation and Detection:

In AES, the sample is bombarded with a focused electron beam. These primary electrons interact with the atoms at the surface, causing the emission of Auger electrons. The emitted Auger electrons have energies characteristic of the elements present and their chemical environments. These energies are unique to the specific atoms and electron states involved in the Auger process.

- Energy Analysis:

The emitted Auger electrons are energy analyzed using a spectrometer. The energy of each Auger electron is measured, and the resulting spectrum shows the number of electrons detected at each energy level. The peaks in the Auger electron spectrum correspond to the energies of the emitted Auger electrons. Each peak is associated with a specific element or chemical state in the sample.

- Elemental Identification and Chemical Information:

By analyzing the energy spectrum of the emitted Auger electrons, researchers can identify the elements present on the sample’s surface. The energy differences between the peaks provide insights into the chemical bonding and chemical shifts of the elements. This information helps identify the chemical states of the surface atoms and provides details about the material’s composition and surface chemistry.

- Surface Sensitivity and Depth Profiling:

AES is a surface-sensitive technique, primarily probing the top few atomic layers of a material. However, depth profiling can be achieved by using ion sputtering to remove material layer by layer while continuously measuring the Auger electron spectrum. This enables researchers to investigate the elemental composition as a function of depth in the sample.

- Applications:

AES is widely used in materials science, nanotechnology, and surface chemistry to analyze the composition of metals, semiconductors, ceramics, and insulating materials. It is valuable for studying surface contaminants, thin films, and interfaces. AES is especially sensitive to surface chemistry changes induced by adsorption, oxidation, and other surface reactions.

In summary, Auger Electron Spectroscopy provides detailed information about the elemental composition and chemical states of a material’s surface. By detecting the characteristic energies of Auger electrons, researchers gain insights into the surface chemistry and bonding, making AES a valuable tool for surface analysis and materials characterization.

Why use Auger Electron Spectroscopy?

Auger Electron Spectroscopy (AES) is a powerful surface analysis technique that offers several advantages, making it a valuable tool in various scientific and industrial applications. Some reasons why one would use Auger Electron Spectroscopy are:

- Surface Sensitivity:

Auger is particularly well-suited for studying the properties of a material’s surface. Its high surface sensitivity enables researchers to analyze the top few atomic layers of a sample. This capability is crucial when investigating surface modifications, adsorption processes, and contamination. Auger’s ability to focus on surface interactions makes it an invaluable tool for understanding how materials behave at the interface with their surroundings.

- Elemental Identification:

Auger is adept at identifying the elements present on a surface, even at trace levels. By measuring the energies of Auger electrons emitted during the relaxation of core-level vacancies, the technique can accurately determine the types of atoms constituting a material’s surface. This is particularly useful when assessing elemental composition, identifying impurities, and detecting trace contaminants that might impact material performance.

- Chemical Bonding Information:

Beyond elemental identification, Auger provides insights into the chemical bonding and chemical states of surface elements. The energy shifts and intensities of Auger peaks offer valuable information about the chemical environments of atoms. Researchers can discern different oxidation states and coordination configurations of elements, enabling a deeper understanding of surface chemistry and reactivity.

- Quantitative Analysis:

Auger allows for the relative quantification of elements on a surface. By measuring the intensity of Auger electron signals and applying appropriate calibration standards, researchers can estimate the concentration of different elements. This quantitative capability is crucial for assessing compositional variations, tracking changes in elemental ratios, and verifying material specifications.

- Surface Contamination Detection:

Auger’s exceptional sensitivity makes it highly effective for detecting surface contaminants and adsorbed species. Whether analyzing residues from processing, environmental contaminants, or unwanted films, Auger can identify and characterize these substances. This is especially relevant in industries such as electronics, where even small levels of contamination can have significant effects on device performance.

- Depth Profiling:

Auger offers depth profiling capabilities, allowing researchers to investigate compositional changes as a function of depth. This is achieved by sequentially removing material layers through ion sputtering while monitoring the resulting Auger spectra. Depth profiling is crucial for understanding layered structures, coatings, and interfaces, providing insights into how material composition varies beneath the surface.

- Materials Characterization:

Auger is widely used in materials science to characterize various materials, including metals, semiconductors, ceramics, and insulators. Its ability to provide detailed chemical information about a material’s surface aids in understanding material properties, assessing surface modifications, and evaluating interface phenomena, contributing to advancements in materials research and development.

- Thin Film Analysis:

Auger is a valuable technique for analyzing thin films and multilayer structures. By studying the Auger spectra obtained from different layers, researchers can determine film thickness, assess compositional variations across layers, and gain insights into interfacial interactions.

- Quality Control and Failure Analysis:

Auger plays a crucial role in quality control within industries like electronics. It helps ensure that material quality meets specified standards by detecting impurities, verifying elemental composition, and identifying deviations from desired material properties. Additionally, Auger is used in failure analysis to investigate the causes of device malfunctions and material degradation.

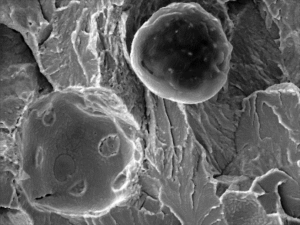

- Biomedical and Biomaterials Research:

In biomedical and biomaterials research, Auger contributes to understanding surfaces of cells, tissues, and biomaterials. It aids in studying protein adsorption, assessing biocompatibility, and investigating the interactions between biomolecules and surfaces. Auger’s ability to provide chemical insights at the nanoscale supports advancements in areas like tissue engineering and medical device development.

In summary, Auger Electron Spectroscopy offers a suite of advantages that make it a versatile and indispensable tool for investigating surface properties, chemical composition, and interactions at the atomic and molecular level.

Applications for Auger Electron Spectroscopy

Semiconductor Device Fabrication

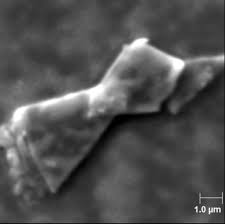

Auger finds extensive use in the semiconductor industry, particularly in the fabrication of microelectronic devices. It plays a vital role in ensuring the quality and reliability of integrated circuits and microchips. Auger can detect trace contaminants and impurities on semiconductor wafers, helping to identify potential sources of device failures. Moreover, it aids in evaluating thin film depositions, detecting interface reactions, and assessing the composition of different layers within complex semiconductor structures.

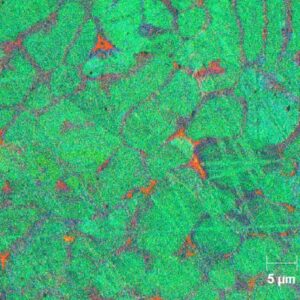

Materials Coating and Surface Engineering

Auger is essential for studying the effectiveness of coatings and surface treatments applied to various materials. In industries such as automotive and aerospace, where coatings protect against wear, corrosion, and environmental conditions, Auger is used to analyze coating thickness, composition, and bonding at the surface. This information guides the optimization of coating processes, ensuring durability and performance of coated materials in demanding applications.

Environmental and Geochemical Studies

Auger plays a significant role in environmental science and geochemistry. Researchers use it to investigate the chemical composition of soil, sediments, and atmospheric particles. Auger can identify the presence of specific elements and compounds in environmental samples, helping to monitor pollution levels, understand pollutant sources, and track changes in soil and sediment composition over time. This application contributes to assessing environmental quality and guiding remediation efforts.