A fuel cell is an electrochemical device that converts the chemical energy of hydrogen (H2) directly into electrical energy, heat and water without the electrolyte and electrodes burning up. Several types of fuel cells exist depending on the operating temperature and on the electrolyte and electrode materials. One of the actual challenges in fuel cell research is to reduce the operating temperature which can reach up to 1000°C. PCFC (Protonic Ceramic Fuel Cell) cells operate at around 500-600°C and are based on proton (H+) diffusion. A hydrogen fuel cell is usually made up of a set of cells, stacked together, to allow sufficient energy production for the desired application.

A study on the behavior of batteries during reduction phases

There are many types of hydrogen fuel cells on the market today, but research is also very active, in the midst of the replacement of fossil fuels. The main objectives of these projects are to improve the efficiency and durability of these batteries.

The study presented below concerns protonic batteries made of ceramic: PCEC Protonic Ceramic Electrochemical Cells, and their behavior during the reduction phase. It is part of two thesis topics (Mélanie François, defended in 2021, and Victoire Lescure, in progress) within the Carnot Bourgogne interdisciplinary laboratories, as well as the FEMTO-ST Institute, which has been studying the materials of these fuel cells for several years. The objective is to develop, optimize, and physically and electrochemically characterize the various components of a PCEC. This work has been published in the journal Membranes.

X-ray tomography is an imaging technique that allows the characterization of the scanned sample in 3 dimensions. The results obtained are presented in the form of virtual sections. The information obtained is generally represented by different levels of grey reflecting the density of the elements of the material scanned. The denser the element, the lighter the grey level, and vice versa for less dense elements.

The manufacturing process of proton cells induces structural variations, which can sometimes cause defects to appear. These cells will also be subjected to redox cycles, which will have an impact on their structure. Tomography allows us to characterize these elements with good resolution, in 3 dimensions, on a representative volume of the material studied.

The present document illustrates by a series of measurements some examples of characterization of manufacturing defects and observation of the evolution of the ceramic microstructure during the different phases of manufacturing and operation.

Method used

Studied samples

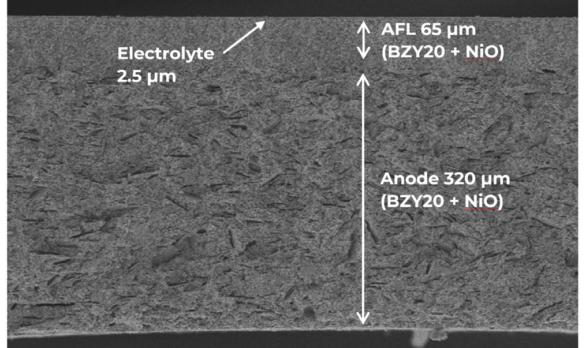

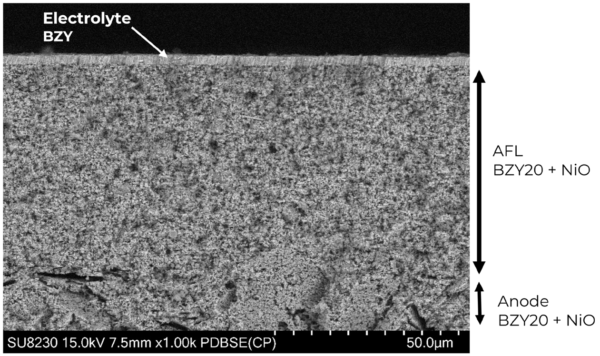

The samples used are half-cells, consisting of a 2.5 μm Yttrium-doped Barium Zirconate (BZY) electrolyte layer, a 65 μm Functional Anode Layer (AFL) and an anode of about 300 μm, both composed of BZY20 and Nickel Oxide (NiO) with different compactnesses.

Learn More?

Please click on ‘Request Application Note’ and we will send you the full application note ‘Hydrogen Energy – Major technical challenges for fuel cells’.