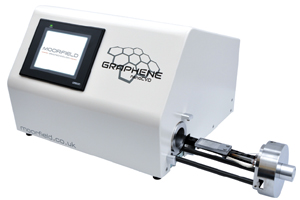

ANNEAL vacuum annealing systems from Moorfield are optimized for the thermal treatment of 2D materials and wafers under controlled atmospheres. Substrates are supported face-up on stage-top platens that are situated centrally inside a stainless-steel high-vacuum chamber fitted with appropriate heat shielding and a shuttered viewport. Heating is via a heat source located beneath the platen. Maximum temperatures up to 1000 °C are possible—depending on the heating technology used. ANNEAL systems are highly modular and can be configured for a wide range of applications.

Key Features and Benefits

Key Features and Benefits

♦ System can be fitted with up to 3 Mass Flow Controllers

♦ Heating up to 1000°C for substrates up to 6” diameter

♦ Heating resolution up to ± 1°C

Applications

Applications

♦ Thermal treatment of 2D materials and wafers

♦ Turbomolecular pumping system, base pressure < 5 x 10-7 mbar

♦ Cleanroom compatible and equipped for easy servicing

About Moorfield

Since 1989, Moorfield has specialized itself in vacuum deposition equipment (PVD/CVD) for pilot-scale industrial production and high-end educational institutions. Their system designs involve extensive modularity which results in flexible solutions. The product range, which consists of different functionalities, is sized for deposition of metals, inorganics and organics.

Why Moorfield?

♦ Excellence in vacuum technology since 1989

♦ Laboratory equipment to match your research

♦ needs

♦ Multiple platforms and infinite options

Related products

Related products

Dedicated soft-etching instruments

Compact, turn-key and scalable CVD system for rapid synthesis of high quality graphene