In the last decade, additive manufacturing has been adopted by the industry because of its advantages with respect to traditional subtractive and formative methods. The possibilities offered by additive manufacturing for creating complex geometries cannot be matched using traditional manufacturing methods. However, it has some disadvantages like the lack of standardization, the difficulty to control the dimensions and surface properties of the

produced samples, and the need for a post- processing step on most cases.

In this study, we wanted to measure the changes that a single parameter can produce on the final properties of a manufactured part by measuring form and surface texture.

Measurements

STUDY 1. FORM DEVIATION AS A FUNCTION OF PROCESS PARAMETERS (MATERIAL AND OTHER)

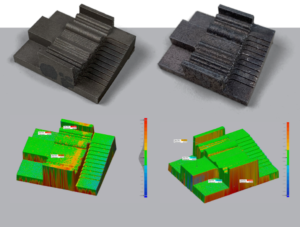

For this case study, we used Selective Laser Melting technique to produce the same test specimen twice but with two different materials. By doing this, we wanted to see the influence that this change would have on the overall form of the manufactured part. We chose Titanium alloy Ti6Al4V and Aluminum alloy AlSi10Mg to be our test materials because of their wide use on the aerospace and medical industry [1].

With the S wide we measured these two samples and also a reference sample and compared them with a 3D comparison software.

Figure 1. Photos of the manufactured samples and screenshots of their 3D comparisons (Left: Ti6Al4V. Right: AlSi10Mg)

Learn More?

Please click on ‘Request Application Note’ and download the full application note ‘Characterizing process-induced form and surface texture change in additive manufacturing’.