Laser processing enables the development of engineered surfaces by applying textures, producing enhanced functional performance such as surface friction, tactile behavior, wetting properties, and many more. Laser processing using ultra-short pulses durations in the picosecond and femtosecond region allows surface texturing with highly defined micro geometries, edges, and finishes. 5-axis laser processing enables the seamless texturing of three-dimensional components to be carried out having complex profiles.

Measurements

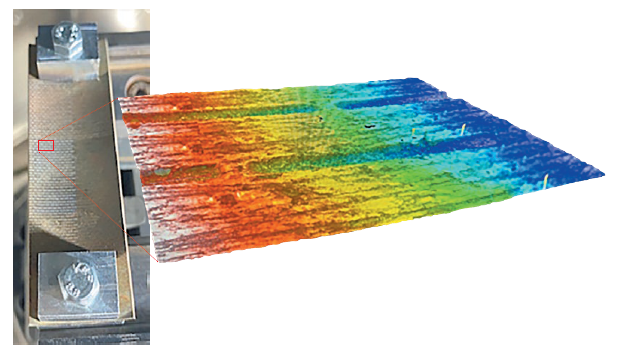

The Sensofar S neox 3D optical profilometer has become an integral part of the development of surface textures at the MTC. In a collaborative experimental study with an automotive company, as part of the European funded Prometheus project, surface textures were developed at the MTC and applied to the curved surfaces of automotive combustion engine cylinder liner segments using a femtosecond laser system. Figure 1 provides an example of a laser textured cylinder liner segment and the texture features using 3D profilometry.

Figure 1. A automotive cylinder liner segment showing the laser produced texture and a 3-D profile capture of the textured surface

Learn More?

Please click on ‘Request Application Note’ and download the full application note ‘The evaluation of texture geometries of automotive engine cylinder liners produced by femtosecond pulsed laser processing’.