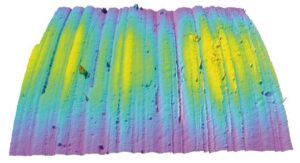

How 3D Non-contact surface measurement can improve your Additive Manufacturing process

David Paez, Sensofar

David Paez, Sensofar

David Paez, will show how specific non-contact 3D optical metrology techniques can provide a complete solution for the characterization of the form and texture of additively manufactured parts. Through case studies, we will show how to measure and analyze as-built to post-processed samples.

Webinar Topics:

♦ How can additive manufacturing processes benefit from 3D optical metrology?

♦ Comparison of the most used techniques for surface texture measurement on additive manufacturing parts

♦ How to characterize form and surface texture of additive manufacturing parts

Application: Characterization of the form and texture of additively manufactured parts

Optical Metrology Techniques, the Masterclass!

Optical Metrology Techniques, the Masterclass!

Roger Artigas, Sensofar

Roger Artigas, Sensofar

Roger Artigas, President & CTO at Sensofar Metrology presents four optical measurement techniques found in many of today’s optical metrology systems and simplify the complexity of these optical techniques and provide you with a guide to know when and how to use them.

Webinar Topics:

♦ Working principles of the main optical techniques for the surface metrology

♦ Comparison of the most used technologies in the market

♦ Benefits of combining the 3D optical techniques

Application: Surface measurements with non-contact optical technologies

All you need to know about surface measurements in tooling

All you need to know about surface measurements in tooling

Alberto Aguerri, Sensofar

Alberto Aguerri, Sensofar

Alberto Aguerri, VP Sales at Sensofar Metrology presents the webinar: ‘All you need to know about surface measurements in Tooling’. The designing and manufacturing of tools directly affects the production quality of the end-user industry and metrology requirements in the tooling market are more challenging every day.

Webinar Topics:

♦ Tips for the measurement of samples with similar shape (drills, screws, cutting tools…)

♦ How to measure and how to analyze? (features like, roughness, wear, shape, CAD comparison…)

♦ General advice with real examples to find the best solutions for your day-to-day in the field of tooling surface measurement

Application: Surface measurements for tooling, like roughness, radius, wear etc.

Best tips for Dental Implants surface characterization

Best tips for Dental Implants surface characterization

Alberto Aguerri, Sensofar

Alberto Aguerri, Sensofar

Alberto Aguerri, VP Sales at Sensofar Metrology presents the webinar: ‘multiple surface measurements on dental implant applications’. An intense amount of implant research has been focused on the development of new surface treatments to increase surface roughness, aiming to enhance the biological response and ultimately, the osteointegration.

Webinar Topics:

♦ How to evaluate the roughness of a dental implant?

♦ Other topographic evaluations (different surface color, reflectivity, shape, coatings, texture…)

♦ What to find in a 3D topography that you cannot find in a 2D topography?

♦ The most suitable techniques for Dental implants Research and Quality Control

Application: Surface characterization for Dental Implants, for roughness and form

Broaden your horizons with the New Sensofar System S wide

Broaden your horizons with the New Sensofar System S wide

Alberto Aguerri, Sensofar

Alberto Aguerri, Sensofar

Alberto Aguerri, VP Sales at Sensofar Metrology presents the webinar to Learn all about Sensofar’s new exceptional 3D Optical Profiler which expands metrology towards a larger field of view for surface roughness measurements.

The S wide integrates the benefits of a digital microscope into a hi-resolution, fast scanning measuring instrument.

Webinar Topics:

♦ This new system improve routine operation through ease of use, with one-shot height measurements up to 40 mm, without Z-scanning

♦ Achievement of sub-micron height repeatability over entire extended area

♦ Color acquisition with the best resolution thanks to the integrated 5Mpx camera

♦ Form deviation from 3D CAD models for an effective integration to daily internal processes

Application: Rapidly measure samples in 3D for large field of view with high resolution. Used in advanced manufacturing, archaeology, paleontology, electronics, medical, molding, optics, etc.

New Technologies for 3D Surface Metrology: Confocal Fusion & Continuous Confocal

New Technologies for 3D Surface Metrology: Confocal Fusion & Continuous Confocal

Dr. Albert Sánchez, Sensofar

Dr. Albert Sánchez, Sensofar

Albert Sánchez, Product Specialist at Sensofar Metrology, presents two new technologies: Continuous Confocal and Confocal Fusion. Both technologies combine key features of the existing Focus Variation and Confocal techniques.

Webinar Topics:

♦ Continuous Confocal

♦ Confocal Fusion

Application: Dental implants, carbon surfaces, etc.