Sample surfaces are inevitably contaminated with hydrocarbon due to sample preparation or storage. The ZONE II desktop sample cleaners/desiccators gently remove that contamination to reveal the true surface of your specimens.

The innovative ZONE II Desktop Sample Cleaners use UV-based cleaning technology to minimize or eliminate hydrocarbon contamination for electron microscopy imaging. ZONE offers easy-to-use cleaning for pre-analysis sample preparation, ensuring the best possible data from your SEM & TEM samples.

How do UV Ozone Sample Cleaners work?

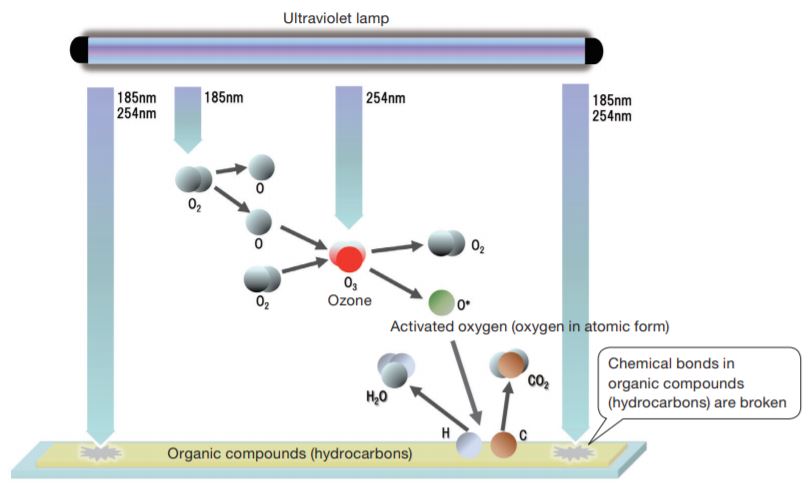

The UV ozone sample cleaners utilize two different techniques to remove hydrocarbon contamination from the surface by (1) direct decomposition of hydrocarbons under influence of UV and (2) by oxygen radicals. The UV lamp of the sample cleaner has two dominant radiation wavelengths, at 185 nm and 254 nm. The 185 nm UV component breaks oxygen molecules (O2) into two oxygen atoms (O), which subsequently bind to oxygen molecules to form ozone (O3). Ozone is dissociated under influence of 254 nm into activated oxygen (O*) and normal oxygen molecules (O2) again. Activated oxygen atoms establish chemical reactions with hydrocarbons on the sample surface, which then dissociate into volatile low-molecular weight molecules such as CO2 and H2O.

By setting the vacuum level of the sample cleaner, the desired contamination cleaning strategy is emphasized. At lower pressure levels, there is a low amount of oxygen and less activated oxygen is created. Most cleaning will then be performed by decomposition of hydrocarbons under direct UV irradiation. This strategy is in general more suitable for materials with a high surface energy like metals and ceramics. Materials which are more sensitive for UV damage, like polymers, need a different approach: the pressure in the sample chamber will be increased to stimulate the production of ozone and to increase the activated oxygen cleaning activity.

Why use UV Ozone Sample Cleaners?

UV ozone sample cleaners are ideal to remove hydrocarbon contamination on SEM samples. Compared to aggressive plasma cleaners, our sample cleaners have a more gentle approach. There is no sample damage caused by an ion bombardment and the best cleaning strategy, either direct UV irradiation or treatment with activated oxygen, is easily adjusted based on your sample material. In only a few minutes, your sample is free of hydrocarbon contamination.

Besides the cleaning properties, the sample cleaners can operate without activating the UV source and act as a controlled sample environment. Samples can be stored in low-vacuum conditions, similar to a desiccator. This functionality is also useful for samples which exhibit outgassing at low-vacuum.

These desktop systems have a lab-friendly footprint and belong in every lab with a FE-SEM, independent of SEM/TEM manufacturer. With the built-in ozone trap there is no need for expensive fume hoods. Additional inert gasses like argon are unnecessary; the cleaner only requires a 220V power supply.

Applications of UV Ozone Sample Cleaners

Indium Tin Oxide

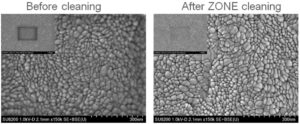

Indium tin oxide (ITO) is a conductive material with optical transparency. It can easily be deposited as a thin film and is therefore widely applied in the aerospace industry and as conductive coating for liquid crystal displays (LCDs). The following image demonstrates the effect of cleaning an ITO thin film on a glass substrate after treatment with the ZoneSEM II. Before cleaning, the typical ‘black box effect’ is visible. Sample cleaning clearly improves image quality and gives the user more time for image acquisition

EDX Measurements

Sample cleaning is also beneficial for analytical SEM techniques such as energy-dispersive X-ray spectroscopy (EDX). Removal of the hydrocarbon film layer increases the signal to noise ratio and improved EDX mappings are acquired. Similar effects are observed in other measurements which need more acquisition time, like EBSD measurements.

(S)TEM samples

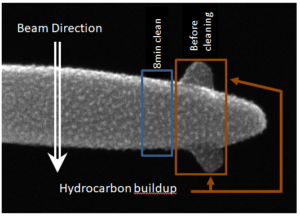

In TEM and STEM environment, hydrocarbon agglomeration occurs on both side of the sample. For this reason, the ZoneTEM II cleans both sides of the sample. The following image demonstrates the nature of electron beam induced deposition (EBID) by a transmitted electron beam. Before cleaning with the UV ozone sample cleaner, this nano-pillar shows hydrocarbon contamination on both sides. After 8 minutes of cleaning, the hydrocarbons on the surface are removed and no hydrocarbon build up occurs.